An OEMs Guide to Selecting PCB Manufacturers

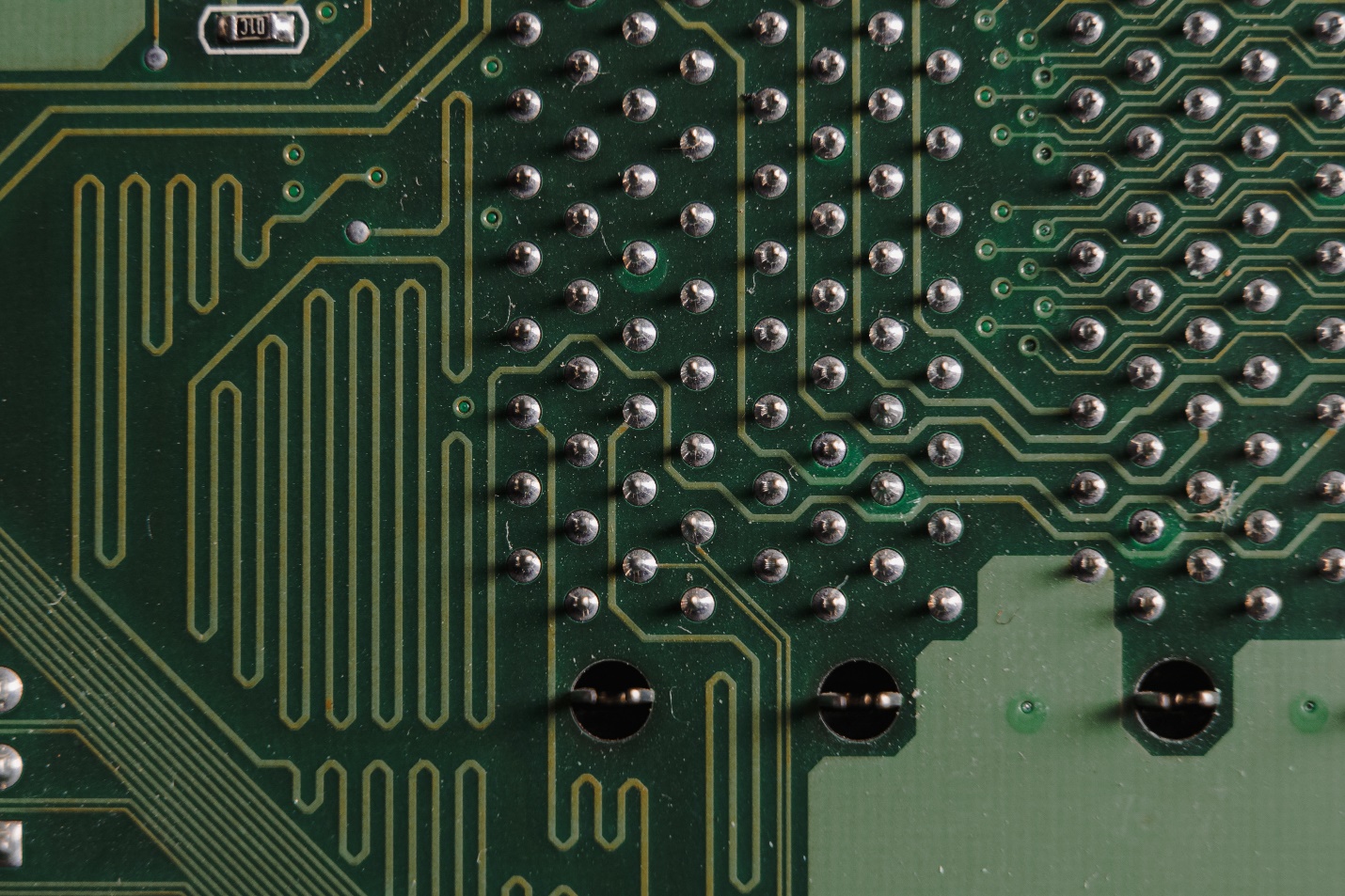

When we discuss the partnership between an OEM and an EMS provider, the base of that partnership relies on the EMS company’s capabilities when it comes to creating printed circuit boards (or PCBs). The PCB is the central part of electronic equipment production and is what allows electronic products to run according to their function. There are several considerations an OEM must have before finalizing which PCB manufacturer they want to work with. Today, we’ll go over a few of those considerations in detail.

Professional Qualifications & Team Certifications

One of the best ways to know if a company you are working with is reliable is to check the qualifications they have. This is especially true for PCB assemblies, where there isn’t much room for error in production.

PCB quality can differ from one manufacturer to the next. While some may have a very low rate of faulty PCBs, others might waste more material trying to fill up the quota of non-faulty pieces. Reliable quality means that you don’t have to experience production delays, can work with fewer buffer materials, and have to worry less about being sent faulty final products.

While it can be difficult to know exactly which PCB manufacturers can promise high quality and deliver on it, checking ISO certifications is usually a good indicator of whether a company can consistently provide high-quality work.

Specializations in Industries

One significant factor that decides whether you can work with a particular company or not is their specific expertise for certain types of products from certain industries. Some of the best PCB manufacturers may not be able to work with you if they lack experience fabricating the exact type of circuit boards that you need. Find someone who is a good fit for you in both of these aspects.

Track Record on Delivering Products

For any production project, deadlines are crucial in dictating whether a project was successful. Products need to be ready before a specific time for numerous reasons. Their place in the market may become obsolete soon, or the company that placed the order for the product may not buy them after a certain point. Check what track record your potential PCB supplier has for product delivery for their other clients before making your choice. Don’t be afraid of reaching out to other clients of an EMS service to ask for feedback on their projects.

Looking for a good PCB assembly service has gotten a lot easier with our online platform; Find an EMS. For OEM providers looking for reliable EMS suppliers, this platform can help them connect with a number of different manufacturers in North America. Get in touch with our team to learn more about the platform and create a profile for your company.